Unlocking Innovation: The Advantages of Membrane Switches Over in Modern Modern Technology

Membrane layer changes stand for a crucial innovation in customer interface technology, distinguished by their lightweight construction and exceptional longevity. The design adaptability integral in membrane layer changes permits for tailored appearances and tactile responses, substantially boosting user interaction.

Overview of Membrane Switches

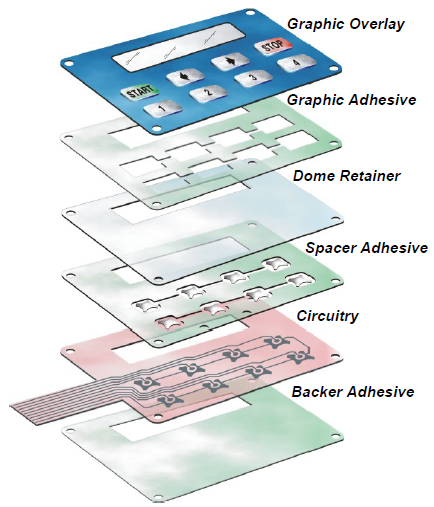

Membrane buttons are crucial parts in modern electronic devices, serving as user interfaces that help with interaction in between customers and devices. These buttons contain numerous layers, generally including a graphic overlay, spacer layer, and a published circuit layer. Membrane Switches. The graphic overlay supplies visual instructions, while the spacer layer separates the circuit layers till a switch is pressed, registering and completing the circuit individual input

Produced using sophisticated printing and layering techniques, membrane buttons can likewise include distinct structures and shades, contributing to visual allure. Their adaptability encompasses markets such as medical, automobile, and consumer electronic devices, where they play a critical function in product performance and design. As innovation advancements, the importance of membrane switches remains to expand, strengthening their position in the landscape of modern-day digital user interfaces.

Sturdiness and Dependability

The longevity and integrity of membrane switches are basic features that enhance their allure in numerous applications. These switches are developed to stand up to severe atmospheres, making them perfect for use in markets such as vehicle, clinical, and industrial machinery. Normally created with durable materials, membrane switches withstand wetness, dust, and chemical direct exposure, which ensures consistent performance also in tough conditions.

Furthermore, the lifecycle of membrane layer buttons is substantially prolonged due to their resistance to wear and tear. Unlike standard mechanical buttons, which can break down with time, membrane layer changes maintain their performance through substantial usage. This strength is especially important in high-frequency applications where dependability is non-negotiable.

Additionally, membrane layer buttons are less vulnerable to failure from mechanical shock or vibration, providing a reputable interface for users. Their capability to function effectively across a large range of temperature levels better adds to their integrity in diverse environments. On the whole, the durability and reliability of membrane layer switches not just minimize maintenance expenses yet also boost customer fulfillment, making them a superb selection for modern technology applications.

Style Versatility

An exceptional aspect of modern-day membrane layer buttons is their design versatility, which permits modification to meet certain individual needs and visual choices. This versatility is crucial in numerous sectors, enabling producers to develop special user interfaces that straighten with product branding and customer interaction objectives.

Membrane layer switches can be customized in terms of form, size, and visuals layout, promoting the assimilation of logos, color design, and practical aspects that resonate with completion user. This adaptability is especially advantageous in industries such as customer electronics, clinical gadgets, and industrial tools, where aesthetic allure and capability must coexist sympathetically.

Additionally, making use of innovative printing innovations permits for complex styles and high-resolution graphics, improving the general appearance of the user interface. Different materials can also be employed to attain varying tactile sensations, ensuring that the button not just looks excellent but really feels right to the user.

Boosted Customer Experience

While interface have actually advanced substantially, the assimilation of membrane switches plays a crucial duty in enhancing individual experience throughout various gadgets. These buttons provide a seamless user interface that is both instinctive and receptive, allowing customers to connect effortlessly with technology. this post Their tactile responses is made to provide reassuring verification without the bulk of traditional mechanical switches, contributing to a cleaner and much more effective layout.

In addition, membrane switches can be tailored to fit details individual requirements, guaranteeing that controls are easy to understand and easily accessible. This adaptability is especially helpful in creating user interfaces that satisfy diverse individual demographics, including those with varying degrees of tech efficiency. Enhanced durability and resistance to ecological aspects better extend the functionality of these buttons, making them a reputable option for both consumer electronics and commercial applications.

Furthermore, the aesthetic appeal of membrane layer switches can dramatically influence user perception, as they can be developed in numerous shades, appearances, and graphics, therefore improving the overall experience - Membrane Switches. By incorporating functionality with style, membrane layer changes not just improve user communications but also elevate the perceived value of the device, inevitably leading to higher individual complete satisfaction and involvement

Applications Across Industries

Membrane layer buttons have located considerable applications throughout different markets, showing their adaptability and performance in improving device performance. In the healthcare market, these switches are made use of in clinical gadgets and diagnostic equipment, where reliability and convenience of cleansing are extremely important. Their smooth style reduces the accumulation of dust and contaminants, making them suitable for clean and sterile settings.

In the customer electronic devices find more area, membrane layer buttons are increasingly prominent in gadgets such as remote controls, devices, and pc gaming consoles, many thanks to their smooth appearance and responsive comments. The auto market additionally utilizes membrane layer buttons in control panels and control panels, where they add to user-friendly interfaces and resilience against extreme problems.

Furthermore, the commercial field take advantage of membrane buttons in machinery and control systems, where they supply durable procedure and resistance to chemicals and dampness. Their compact and light-weight nature make them ideal for portable gadgets across different applications, including telecommunications and consumer products.

Final Thought

Finally, membrane layer changes stand for a significant development in contemporary Visit This Link technology, supplying countless benefits consisting of toughness, style versatility, and improved individual experiences. Their capacity to endure rough settings and offer customized user interfaces makes them essential throughout different industries. As technology proceeds to develop, the assimilation of membrane buttons will play a vital function in the advancement of cutting-edge tools, inevitably adding to boosted performance and individual complete satisfaction in modern digital applications.

Membrane switches are essential components in contemporary digital gadgets, offering as user interfaces that help with interaction between equipments and individuals. Membrane buttons are lightweight and can be incorporated into compact gadgets, offering a space-efficient remedy compared to conventional mechanical switches.

Unlike standard mechanical buttons, which can degrade over time, membrane switches over preserve their performance via substantial use.While user interfaces have actually developed significantly, the integration of membrane layer switches plays a crucial duty in enhancing user experience throughout various gadgets.In verdict, membrane switches stand for a considerable advancement in modern-day innovation, offering many benefits including toughness, layout versatility, and enhanced individual experiences.

Comments on “Discover the Value of Quality Control in Manufacturing Membrane Switches”